Presseinformationen

BOMAT Heiztechnik GmbH

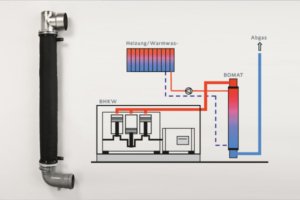

Save money by utilising BOMAT condensing technology for CHP units

At this year’s IFH/Intherm trade fair in Nuremberg, Germany, BOMAT Heiztechnik GmbH will be presenting condensing heat exchangers for combined heat and power (CHP) units with a thermal output of 10 kW and above.

The company will also be showcasing heat exchanger modules for heating technology and cleaning and neutralising systems at Stand No. 7.107 in Hall 7.

Classic CHP units do not fully utilise the heat in their exhaust gas. Many have a thermal efficiency of only 50 %. Much of the heat escapes unused through the exhaust pipe. With BOMAT’s new Minitherm ceramic exhaust condenser, the effectiveness of CHP units can be increased by up to 15 % thanks to optimum use of condensing technology. The Minitherm heat exchangers harness the condensation heat available in the exhaust gas. The heat recovered is fed into the existing heating system or used as process heat. This increases the thermal yield and efficiency of the CHP unit. It also protects the environment, as significantly fewer pollutants are expelled into the air from the chimney.

Long lasting ceramics

As a rule, conventional stainless steel heat exchangers in CHP units are operated above the condensation limit. Nevertheless, condensation may occur at start-up, resulting in corrosion inside the heat exchanger. BOMAT condensing heat exchangers are made of corrosion resistant materials and are used specifically for flue and exhaust gas condensation. With an impressively long service life, BOMAT ceramic heat exchangers are also resistant to the acids generated during combustion (e.g. sulphurous acid, nitric acid and HCl) and compounds containing heavy metals.

Short payback periods

By harnessing the condensation heat and reducing the temperature of the exhaust gases released into the environment, the integration of a BOMAT condensing heat exchanger in a CHP unit soon pays off, as the following sample calculation demonstrates: A CHP unit with around 6000 hours of operation per year and an electrical output of 50 kWel has an exhaust gas temperature of around 120 °Celsius without a BOMAT heat exchanger. The investment required for the exhaust gas heat exchanger including installation and pipework is around €3800. BOMAT technology allows a heat gain amounting to around 45,000 kWh per year, which represents a saving of €2250 – assuming a fuel price of €0.05/kWh. The investment pays off after just 1.7 years, and from then onwards you start saving in earnest.

BOMAT has been developing and manufacturing high quality flue and exhaust gas heat exchangers for over 25 years. As well as numerous other sample applications of the Minitherm and Profitherm series in residential, office and industrial buildings etc., over 12,000 BOMAT CHP condensing heat exchangers have been successfully installed over the past 10 years.

Further information, including details about all aspects of environmentally responsible condensing technology, is available at the trade fair stand or from:

BOMAT Heiztechnik GmbH, Zum Degenhardt 49, 88662 Überlingen, Germany

Telefon 07551-8099-70, Fax 07551-8099-71

email: info@bomat.de

website www.bomat.de

Image captions:

Bomat Heiztechnik GmbH

Free publication provided source is credited – please supply specimen copy